Industrial Gas Filters

Removal of solid particles, liquid aerosols, oil, moisture, and micron-level contaminants from gas streams

Product Introduction

Our industrial gas filters are designed to remove solid particles, liquid aerosols, oil, moisture, and micron-level contaminants from gas streams. Utilizing advanced filtration media and engineered design, these products ensure stable performance, optimal pressure drop, and long operational life in critical industrial applications.

These filters provide a reliable solution for protecting downstream equipment, increasing process efficiency, and complying with quality and safety standards across various industries.

Key Features

High Particle Removal Efficiency

Removal of particles down to micron and sub-micron levels with high efficiency

Minimum Pressure Drop

Optimized design for reduced differential pressure and energy consumption

Corrosion Resistant

Robust construction resistant to harsh operating conditions and corrosive environments

High Pressure & Temperature Operation

Capable of stable performance in demanding operating conditions

Reliable Sealing

Prevents gas leakage and enhances safety

Long Service Life

Reduced maintenance and replacement costs

Applications

Our gas filters are designed for a wide range of industrial applications, including:

Types of Gas Filters

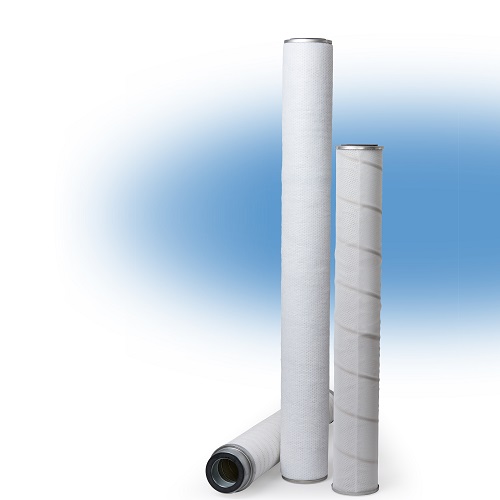

Particulate Gas Filters

These filters are designed to remove solid particles such as dust, pipeline rust, and mechanical contaminants from gas streams. Pleated media with high effective surface area increases particle holding capacity and extends filter service life.

- High filtration efficiency (up to 99.99%)

- Suitable for protecting compressors, turbines, and control valves

- Easy element replacement

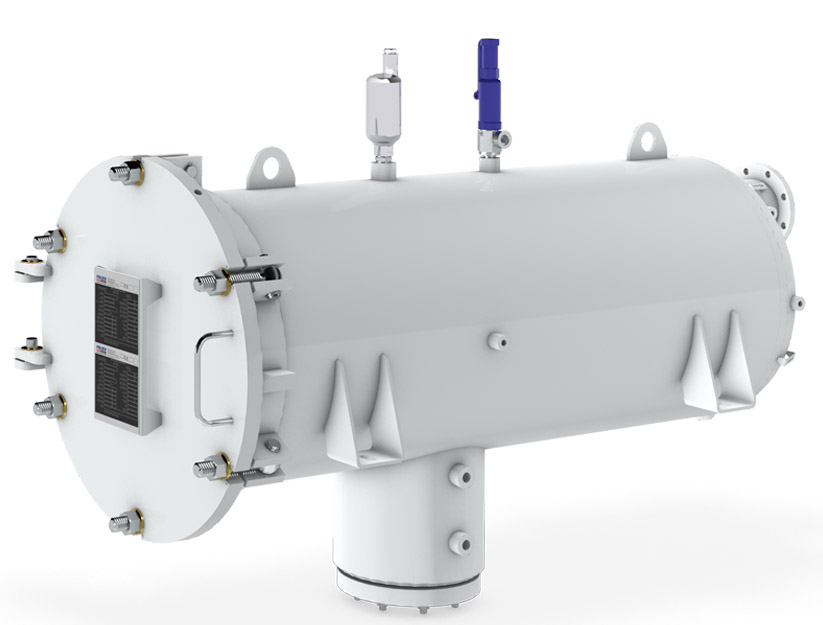

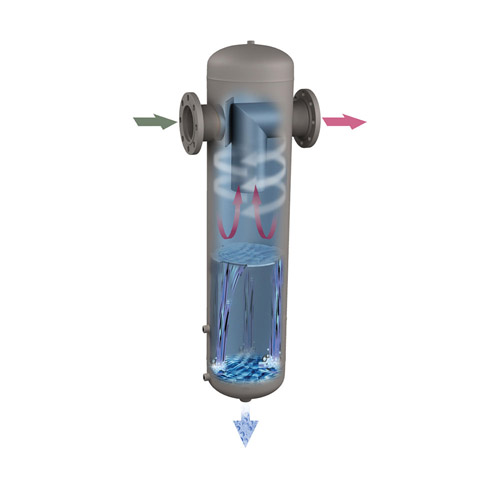

Coalescing Gas Filters

Coalescing filters are used to remove liquid aerosols, oil, and moisture from gas streams. Using coalescence technology, these filters convert fine liquid droplets into larger ones, enabling effective separation.

- Effective removal of liquid particles down to very fine levels

- Improved outlet gas quality

- Increased efficiency of downstream equipment

Activated Carbon Gas Filters

These filters are designed to remove odors, hydrocarbon vapors, and gaseous contaminants through the adsorption process. The use of activated carbon with high specific surface area ensures efficient removal of chemical contaminants.

- Removal of Volatile Organic Compounds (VOCs)

- Improved gas quality for sensitive applications

- Suitable for pharmaceutical and food industries

Typical Technical Specifications

| Housing Material | Carbon Steel, Stainless Steel, or Corrosion-Resistant Alloys |

|---|---|

| Filter Media | Microfiber Glass, Polypropylene, Sintered Steel, or Activated Carbon |

| Maximum Operating Pressure | Application-specific (available in various pressure classes) |

| Maximum Operating Temperature | Depending on media and material type |

| Filtration Rating | From several microns to sub-micron levels |

Gas Filter Applications in Refineries

Gas Filtration in Refinery Processes

Refineries deal with a wide range of gas streams under high pressure and temperature; from fuel gas and process hydrogen to recycle gases and flare lines. The presence of solid particles, hydrocarbon aerosols, water, and corrosive compounds can cause corrosion, erosion, catalyst poisoning, and reduced equipment efficiency.

Engineered industrial gas filters play a vital role in protecting compressors, turbines, catalyst beds, and instrumentation equipment.

Feed Gas Filtration

- Hydrotreating Unit Inlet

- Reformer Unit Feed

- Gas Compressor Feed

- Fuel Gas Transmission Lines

- Particulate Filters

- Filter Separator Vessels

Aerosol and Hydrocarbon Liquid Removal (Coalescing Filtration)

- Recycle Hydrogen Lines

- Separator Drum Outlet Gas

- Return Gas to Compressors

- Gas Recovery Systems

- Coalescing Filters

Catalyst Protection Filtration

In units such as:

Even minute amounts of particles can cause bed pressure drop, reduced catalyst life, and Hot Spots in the reactor.

Guard Filters with high-efficiency elements and sub-micron filtration rating

Turbine and Boiler Fuel Gas Filtration

- Fuel Gas Lines to Turbines

- Refinery Boilers

- Burners and Furnaces

- Prevent burner nozzle clogging

- Prevent turbine blade erosion

- Increase combustion stability

Operating Conditions in Refineries

Filters used in refineries are typically designed for:

- High Pressure Service

- High Temperature

- Corrosive Gases (H₂S, CO₂)

- ASME and API Standard Requirements

Why Sepanta Palayeh Pars?

Sepanta Palayeh Pars, utilizing the latest technical knowledge and valuable experience in the filtration industry, designs and manufactures various types of industrial gas filters in accordance with international ASME and API standards. The gas filters produced by this company, with high quality, excellent efficiency, and long service life, are an ideal choice for oil, gas, petrochemical, refinery, and power plant industries.

- Design and manufacturing according to ASME Section VIII and API standards

- Particulate, Coalescing, and Activated Carbon filter types

- Customization capability based on customer operating conditions

- Step-by-step quality control and performance testing

- Experienced engineering team and strong technical support

- Warranty and after-sales service